Every pool facility wants crystal clear water. For decades we’ve relied on sand filters, but they have limitations – so what’s the alternative?

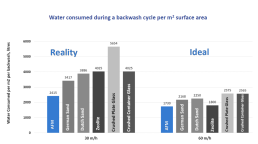

Traditional sand filters suffer from poor efficiency and degradation of performance. They require large amounts of water for backwashing. And the amount required only increases as the filter gets older (due to biofouling and sand compaction).

All the water required for backwashing goes down the drain, which must be replaced. And the new water supplied needs to be treated, heated and chemicals added. Factoring in all of this, and any money saved from choosing the ‘cheaper’ sand option has been lost down the drain in maintenance and upkeep.

Performance degradation & cloudy water

As the performance decreases over time, gradual degradation of water quality will be noticeable. Pool water will become increasingly cloudy – and that’s just what’s visible.

Within in the filter, bacteria can stick to the sand and form biofilms. The biofilm offers a protective layer for the bacteria and even protects them from oxidation by chlorine. The biofilms can cause sand to stick together and blocks up the filter. It also promotes channelling – which reduces the protection against Cryptosporidium and Giardia.

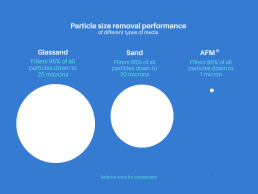

Sand filters with fresh sand can achieve up to 95% removal of particles 25 microns or greater. But there are technologies that can far surpass this.

The solution: Activated Filter Media

AFM® is a highly engineered media made from recycled green and brown glass activated in a 3-step process to become self-sterilising and to acquire superior adsorption properties. The result is a 100% bio-resistant media without issues of biofouling, biocoagulation and wormhole channelling of unfiltered water.

AFM is much more than standard glass-type media. The activation process increases the surface area by up to 300 times much improving the mechanical and electro-static filtration performance. The result, an elite filter media. Switching to this activated glass-type media, can double the performance of a sand filter without any additional infrastructure investments.

The benefits

- Reduced risk of infections by bacteria and parasites such as Legionella, Pseudomonas and Cryptosporidium an absolute minimum

- Produces crystal clear water

- Lower chlorine consumption

- Removes about 50% more organic substances from the water than sand and other glass filter media, thus reducing the formation of harmful Trichloramine and Trihalomethanes (THMs) including chloroform by up to 50%

- Consistent, long-lasting performance for, outlasting all other filter media

- More than doubles the performance of an existing filtration system without the need for additional investments

- Is not subject to biodynamic instability and will never allow untreated water to pass the filter

- Lowers backwash water demand by an average of 50%

- Quick return on investment

- No channelling so provides an effective barrier against Cryptosporidium and Giardia.

- Removes metals and heavy metals from water

- Similar to activated carbon, the surface nano-structure adsorbs pollutants from the water but unlike carbon, it is recharged by just back-washing with water meaning it never needs to be recharged or replaced

- Superior adsorption properties – the surface area of AFM is strongly increased and becomes hydrophobic to filter particles down to 1 micron

AFM provides optimum filtration and backwash performance. It is the most efficient media for fine particle filtration and provides long term and stable filtration performance. On top of that, AFM also offers fantastic backwash efficiency, showing complete superiority at backwash velocities around 30m/h – and the higher the velocity, the more water saved.

How it works

AFM is made from recycled green and brown glass in a state-of-the-art factory, one the most sophisticated and sustainable glass processing factory in the world.

It’s the colouring material that contains metal oxides which act as catalysts that dissociate oxygen and water to create a zone of high oxidation potential to prevent bacteria growing on the surface.

The huge, activated surface area has a strong hydrophobic surface for the adsorption of sub-micron particles and dissolved organic molecules.

The takeaway

AFM is the superior choice for filtration. With significantly lower bacteriological and chemical risks, creating a healthier and safer pool environment. Allowing facilities to achieve crystal clear water with fewer chemicals. Swimmers benefit from clean water with reduced irritants and byproducts – and pool facilities save on overall operating costs for filtration and disinfection.

Need more information? Contact James on 01246 857000 or email: jamesh@sterling-hydrotech.co.uk